For a field test of two types of dispensers, the designers of WeLLDesign are occupied with assembling two series of ten product prototypes. With this field test we will research both the appreciation of the market and the findings of the test group, the end users. The product prototype phase has then come to an end. The production prototyping phase will commence after that. The results of the field test will be evaluated and integrated in the final detailing in 3D CAD. Draft angles, precise wall thicknesses, sprue gates and material decisions are determined together with injection molders and mold makers. After the final tests and with approval of the production prototypes the molds for mass production can be ordered. But first the field test.

As can be read on the productontwikkeling page, fulfills a product prototype all functional demands and has the appearance of the finished product.

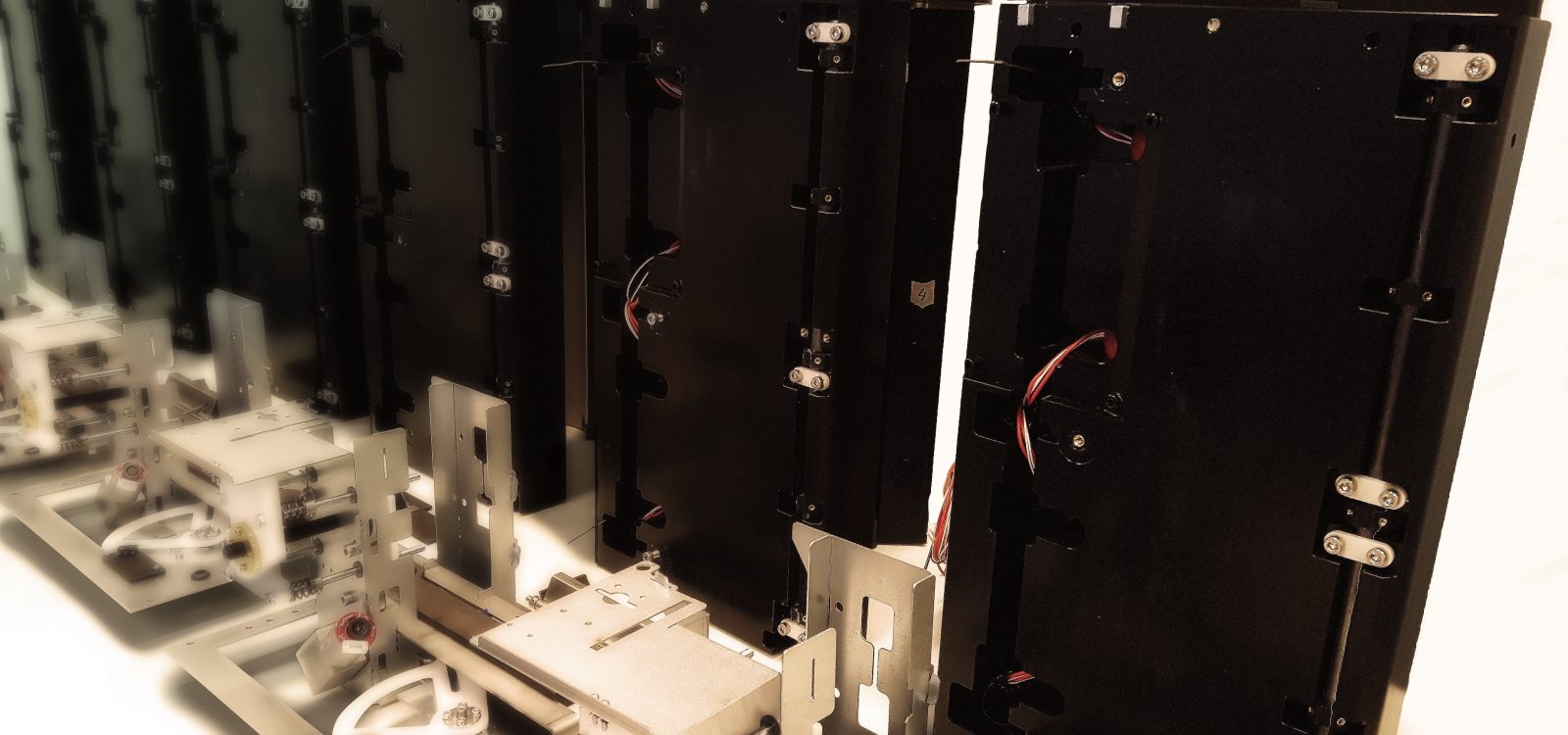

The necessary parts of the prototypes of both dispensers are ordered ten times at our vendors in both domestic and foreign countries, based on our drawings and specifications. These parts have been delivered at our studio and ordered systematically over the past weeks. When these parts are delivered is monitored closely. Sub assemblies are prepared directly. The last holes are tapped, re-bored and deburred to the latest insights, inserts are placed and parts are checked in detail to prevent difficulties during assembly.

Meanwhile all parts are delivered and our designers that work on this project are assembling the field models. The production of these field test prototypes is important, because:

- we can test if the products meet our specifications,

- we can determine if the assembly develops logically and if parts need to be adjusted and/or need to be assembled in a different manner than first was designed,

- with a small series the operation by end users can be testen,

- repeating and consistent errors or irritations can be discovered that could not be detected or predicted beforehand.

We as designers and off course mainly our customers, look forward to the results and findings of the field test of these two dispensers. Often this provides new insights. Both in functionality and robustness. No matter how much we try to foresee everything with systematically design of the development process and temporary tests, field tests provide results and insights to improve. In short, we are very curious towards the findings!