Our design process

Bovenstaande visual toont ons volledige ontwerpproces. De invulling van de verschillende fases passen we altijd aan op wat een project nodig heeft — het zwaartepunt ligt immers niet altijd op dezelfde plek. We vertellen je graag meer over elke fase van dit proces:

Analysis

By conducting research, we gain early insight into the requirements and wishes the product or innovation needs to meet. We make sure we have the design challenge in focus and we identify the opportunities that lie ahead.

— Interviews with stakeholders

— Analysis of relevant trends

— Analysis competitor products

— Customer journey mapping

— Market research

— Technologieën in kaart brengen

— Identifying constraints and opportunities

— Establishing requirements and wishes

Analysis

By conducting research, we gain early insight into the requirements and wishes the product or innovation needs to meet. We make sure we have the design challenge in focus and we identify the opportunities that lie ahead.

— Interviews with stakeholders

— Analysis of relevant trends

— Analysis competitor products

— Mapping customer journey

— Market research

— Mapping technologies and materials

— Identifying constraints and opportunities

— Establishing requirements and wishes

Ideation

We brainstorm and arrive at possible solutions to the design issue. Through the systematic generation of ideas, often through co-creation, and critical selection, we arrive at concepts that meet all requirements.

— Systematic brainstorming

— Co-creation sessions or workshops

— Evaluating ideas based on requirements

— Visualiseren van conceptrichtingen

— Rough estimates of production costs

— Presenting ideas to the stakeholders

— Presenting ideas to the client

— Update requirements based on findings

Proof of concept

We prove the essential working principles of the concept through rapid prototyping. The aim is to verify that the solution works not only in theory, but also in practice.

— Determining assumptions to be verified

— Prototyping with off-the-shelf parts

— Designing and building test rigs

— Testing in our workshop or on location

— Testresultaten evalueren

— Werkingsprincipe bewijzen

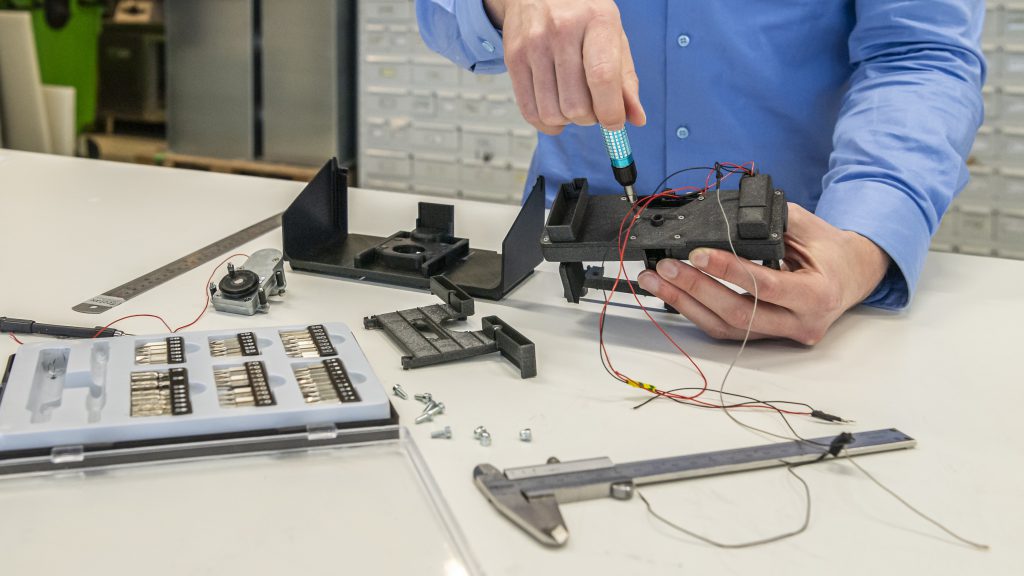

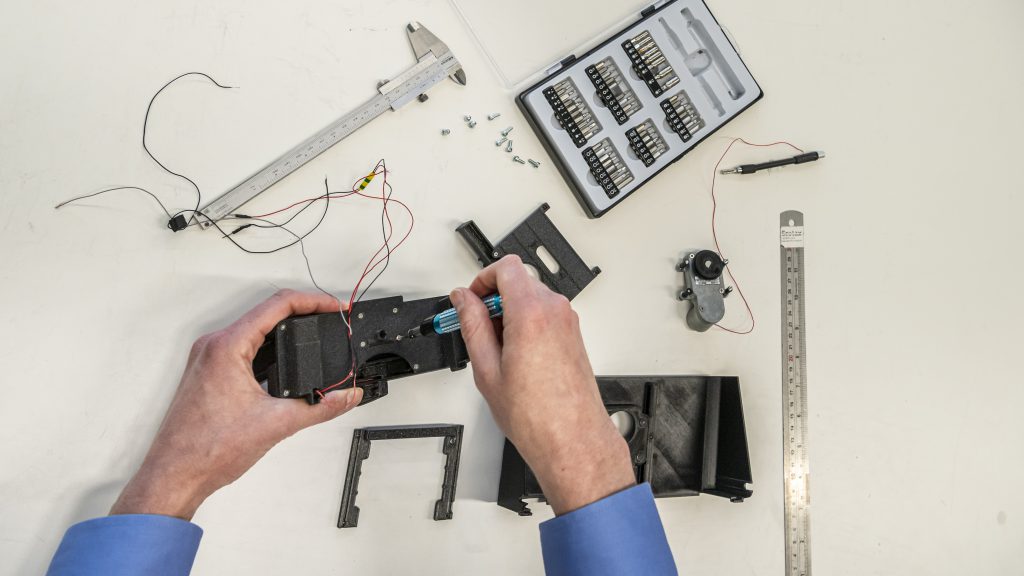

Proof of concept

We prove the essential working principles of the concept through rapid prototyping. The aim is to verify that the solution works not only in theory, but also in practice.

— Determining assumptions to be verified

— Prototyping with off-the-shelf parts

— Designing and building test rigs

— Testing in our workshop or on location

— Interpreting and evaluating test results

— Concluding whether operating principle is successful

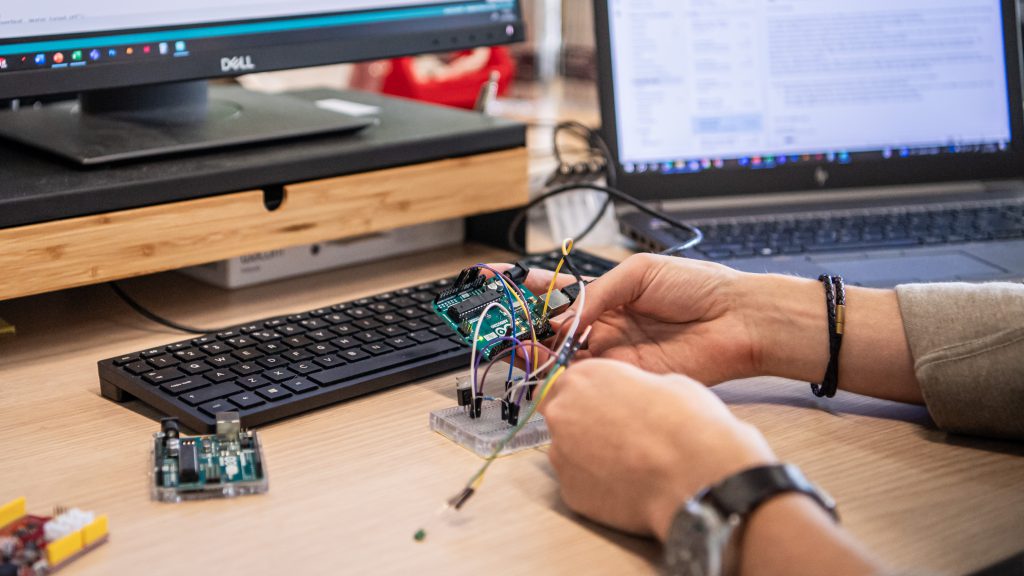

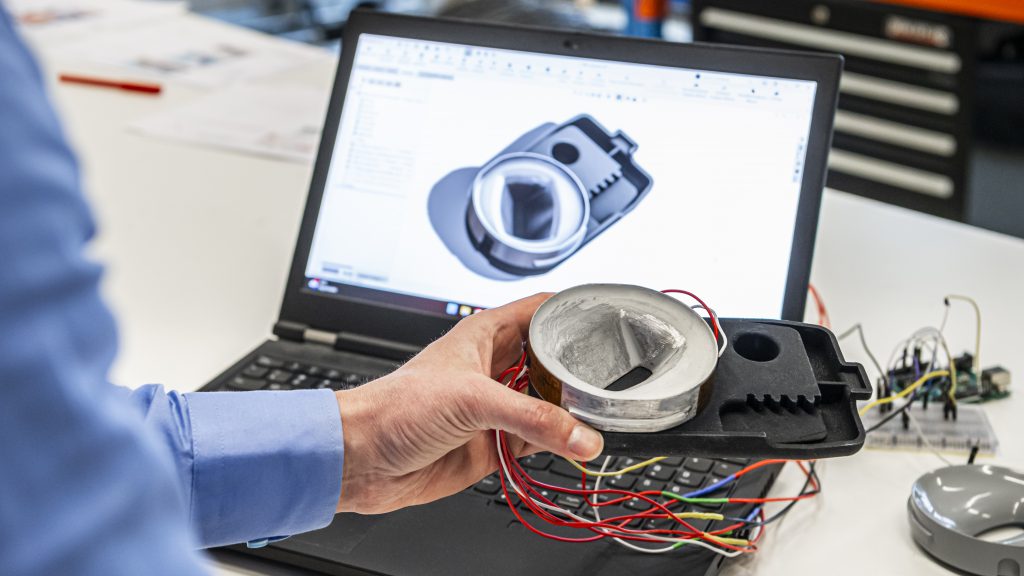

Function prototype

With the function prototype, all previously proven features are being combined in one model. We will then extensively test and evaluate this prototype.

— Prototyping & testing

— Stakeholder feedback sessions

— Researching production methods

— Material research

— Electrical engineering

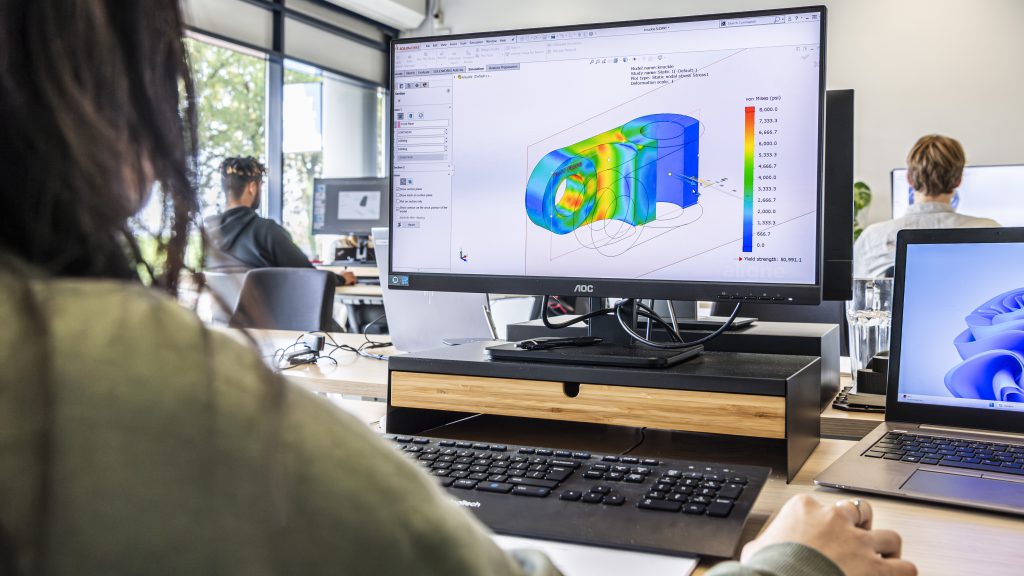

— Strength-analysis

— Patent research

— User tests

— FMEA analysis

Product prototype

The product prototype goes one step further in terms of detail. Not only do all the functions come together, but the prototype is now also correct in terms of geometry and dimensions. In this way we can evaluates how appearance and function come together.

— Prototyping & testing

— Interface design (UX)

— Stakeholder feedback sessions

— Strength and longevity testing

— Finding production partners

— Sourcing parts

— Rough design of supply chain

— Testing and evaluating ergonomics

— Field testing

Production prototype

The production prototype is the last step before actual production. The prototype corresponds 1:1 to how it will be produced. As soon as the production prototype has been approved, production can be prepared.

— Prototyping & testing

— Finetuning details

— Stakeholder feedback sessions

— Setting up production

— Technische documentatie

— Detailed cost calculation

A clear project plan

Before we get started, we make sure that it is clearly agreed what activities we will carry out and what deliverables come with them. We normally do this by means of a project plan. This contains the budget, the details of the assignment, agreements on who is responsible for what and a schedule. After each phase, there will be a point at which the course can be adjusted: sometimes, progressive insight causes us to adjust the strategy somewhat. We follow the client's wishes but will always make recommendations based on our expertise. In this way, we ensure together that the investment is spent as effectively as possible.

Let's Get Started!

Heb jij een ontwerpuitdaging of vraagstuk? We helpen je graag. Neem contact op en we bespreken hoe wij van dienst kunnen zijn.