De techniek van de Senseo voor Douwe Egberts

Challenge

Senseo: innovation in portion pack! Douwe Egberts Faced with declining coffee consumption, Douwe Egberts’ Executive Board defined some major innovation projects, which were given the code name Decathlon. Keywords were individualisation, ease of use and quality.

10 prototypes

DE asked WeLLDesign to execute its Senseo project including project management and manufacturer sourcing. Based on the by DE invented ‘creamy coffee’ system and Waacs’ design, the Senseo Crema was developed and worked out in detail by a team of five in only two years time.

In collaboration with a Chinese manufacturer, WeLLDesign realised ten prototypes. These were transferred to Philips. The result is well known: over 20 million consumers worldwide now enjoy coffee made by their Senseo Crema.

Our contribution

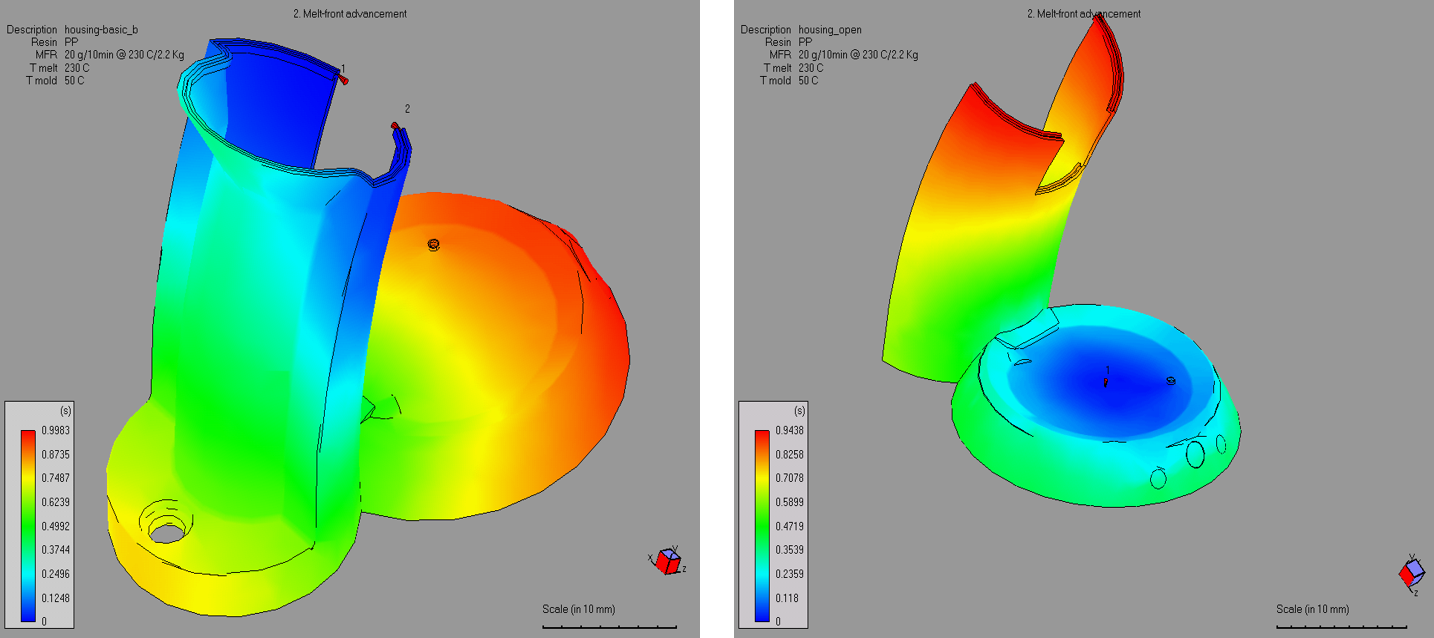

WeLLDesign’s contribution existed of project management, design concepts of the brew chamber and boiler, assistance in patent application, detail engineering, DFA mould flow analysis, sourcing of suppliers, supervision of mould design and prototype build.

Mould Flow Analysis van de Grote Senseo behuizing. Dit geeft inzicht in de vloeiing van het plastic tijdens productie in de matrijs.

Met andere woorden: WeLLDesign heeft er onder andere voor gezorgd dat het kwalitatieve schuimlaagje bovenop de koffie komt te liggen. Dit was een primeur voor koffie die thuis kan worden gezet.

What is your design challenge?

Do you have a design challenge or issue? We are ready to get started for you. Contact us to explore the possibilities.